:Common industrial industrial floorings are divided into two categories

The use of hardboard flooring has a long history in the industry, and is a safe, durable, and inexpensive replacement for traditional coatings

Specific formulation for manufacturing with variable user variability, and according to the needs of each industry, engineering sales experts offer the best option based on the operation of each industrial unit and the customer’s needs.

Bautech’s industrial hardwood flooring is based on minerals, consisting of hard mineral grains, special cements, binders, pigments and steel heads with very high compressive and mechanical strengths.The degree of material hardness varies between 6.5 to 10 mohs per product, depending on the type of product, and the use of this flooring on fresh concrete (dry shake) and on old concrete (as a high performance mortar using a primer layer) for light and heavy use Completely technical and economic justification

The reason for using this floor

Cheap price compares to other similar coatings –

Five-year warranty –

The ability to withstand high mechanical loads (even the movement of chain machines in the type of mortar flooring)

Absorption of oil types, environmental and industrial pollution

Absence of dust and lack of proper bacteria for health, food and soil-sensitive areas

No floor trowel (compared to concrete 350 or other coatings)

unflamable

Non Slip in case of continuous washing

High compressive strength, mechanical, tensile and resistant to static and dynamic loads

The lack of separation of concrete floors from high-speed washing (compared to rocks, ceramics and other traditional coatings)

Possibility of daily delivery of up to 500 to 1000 square meters (provided concrete delivery conditions are available) and concreting concrete hardwood floors simultaneously

Floor integrity with minimal contraction (virtual) joints

Includes industrial and fixed color variations: dark and light gray, pencil, red, brown, green, yellow, beige, light blue and dark

Indications

The coating of industrial surfaces exposed to impact and wear of machinery and abrasion

Concrete surfaces that lack soil is important

Concrete surfaces exposed to oil or water spillage

Industrial floors that require a variety of colors

Spaces that require constant washing and polish the floor

Application

With regard to the above, industrial hard flooring can be used in the following places

Manufacturing factories, manufacturing, warehousing, industrial shops, production and warehouses, food industries, dairies, packaging factories, pharmaceutical industries, oil and gas industries, petrochemical industry, casting industry, rolling mills, heavy industry, power plants Slaughterhouses cold stores, Landscaping, parking lots and so on

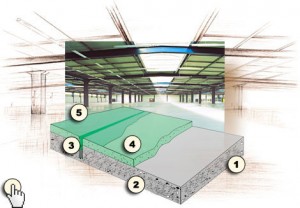

Industrial floors are divided into two categories depending on the type of operation

Industrial flooring for fresh concrete

Industrial flooring for old concrete

Stages of hard concrete construction

Industrial flooring suitable for fresh concrete

In this system, after examining the type of project and information provided by the employer, or according to the design by the employer, the project is implemented or, according to the design and calculations performed by the technical office of the company, takes place

Then, implementation of concrete arrangements such as soil compaction control, molding, reinforcement and finishing of concreting operations, concrete leveling and implementation of a butterframe to prepare the implementation of BAUTEC powder. After the concrete is applied, and after about 1 to 2 hours, the bottle powder is poured on fresh concrete Sprayed powder on concrete, absorb water, find concrete, ready for payment

Then, with single-moths or butterflies butterflies for 7 to 10 hours depending on the weather conditions, the payment is done, which involves the complete mixing of the bottle with fresh concrete

General Specifications of Cement Base Industrial Flooring

The combination of minerals, metal beads, pigments and other additives in the bautec cement base products is designed in a way that is highly versatile in addition to its high compressive strength

No dust production from the floor

No color change and increased glossiness due to traffic (presence of mineral pigments)

– Ease of implementation

Compressive strength up to 160 mega-Pascal

Traffic ability of heavy or even heavy machinery

Non-slip personnel on the floor

Variety of colors and the ability to paint and create margins in industrial niches

Economical cost compared to traditional coatings

Usability on fresh and old concrete

Lack of growth of microorganisms

The lack of knowledge and sufficient information of some employers about new industrial developments sometimes leads to the imposition of costs and excessive spending on various industrial projects. Owners of small units tend to use tiles, ceramics, stone or even mosaics on the floor of factories. In surveys and visits, the number of detonators that have been detonated due to traffic in forklift trucks or water loss, rock or ceramics

It is worth noting that the reason for this is the lack of recognition of other products